Ravenwood has unveiled Anti-Reflection and Deep Learning technologies for its VXR vision pack inspection system. This announcement comes on the heels of the recent integration of a seal contamination detection system.

Both software applications analyse pre-print and linerless labels on packaging. The new Anti-Reflection technology minimises glare and reflections on flow wrap packs, while Deep Learning enhances optical character recognition by accurately decoding diverse font styles, including inkjet dot matrix fonts.

Anti-Reflection and Deep Learning are both adaptable for retrofitting into existing Vision systems in the field. For new machine orders, Deep Learning is now included as a standard feature, while Anti-Reflection is offered as an optional addition.

Anti Reflection

Many meat packers have transitioned from MAP to flow wrap style packaging. This shift is driven by several advantages: reduced material usage, lighter pack weight, lower energy consumption, extended product shelf life, and improved recyclability. While the overall benefits of flow wrap packaging surpass those of MAP, the high reflectivity of flow wrap presents challenges in capturing reliable pack images with standard imaging methods.

To solve this issue, Ravenwood has developed a novel method for reducing the effect of glare and reflection during the imaging process. Supplied as an optional extra, the process is a combination of improved image processing software combined with an enhanced method of illumination. Standard packs can still be inspected as usual.

Deep Learning

Inkjet printers often generate low-quality date codes, and conventional optical recognition software can prove unreliable reading these codes, thus leading to unnecessary pack rejections and contributing significantly to food waste that could otherwise be prevented.

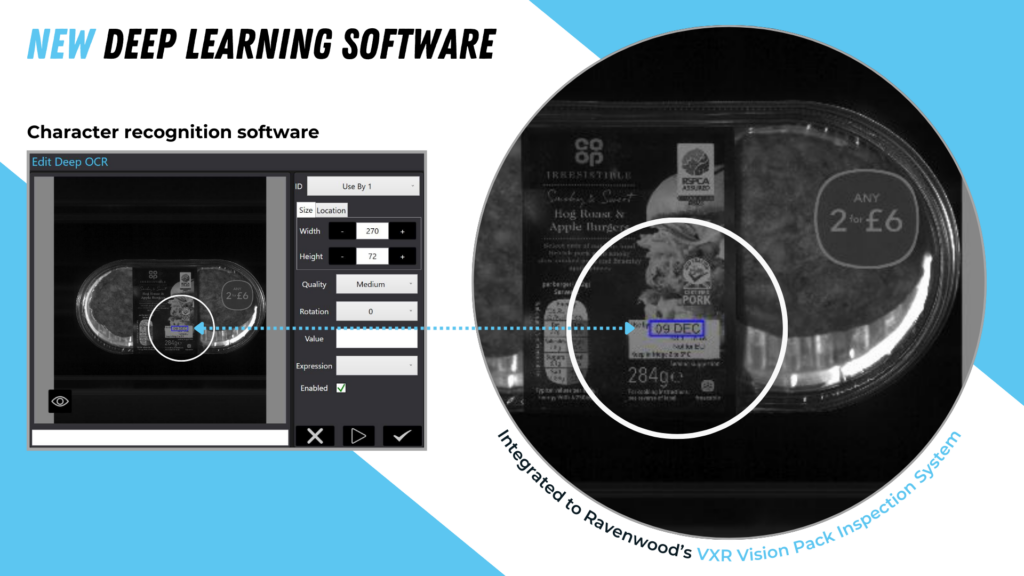

Ravenwood is addressing this issue with advanced Deep Learning technology powered by HALCON software. The improved optical character recognition can eliminate background images, a feat traditional OCR could not achieve. This new software is user-friendly and requires less operator programming, as fonts do not need to be manually taught as required with older methods. It intelligently ignores certain fonts or text below a specific height, such as Julian date codes and line identification codes. The software has been successfully integrated into existing Ravenwood VXR machines at multiple customer sites.

Meeting the Evolving Needs of the Food Industry

Ravenwood is continuously exploring innovative ways to refine and enhance its X-ray inspection and vision technologies. This ongoing evolution is essential to meet industry demands, comply with regulatory requirements, and stay abreast of technological advancements for meeting superior standards of safety and efficiency.

For further information on Anti-Reflection and Deep Learning including seal contamination detection, please contact Marketing on +44(0)1284 749144.