The Ravenwood online meeting for June reported on the first and second quarters of 2021. The update focussed heavily on sustainability and how linerless massively contributes to the benefits of reducing Co2 emissions. Ravenwood’s Directors and Managers presented to its global network of machinery distributors and printer partners.

Due to conflicting time zones, we now provide 2 updates in the same day. The first one at 7am, to our Asia Pacific team and the second at 1pm, to the Rest of the World. This new way of meeting and sharing information globally has been well received.

Our Agenda

- Official Welcome from our Managing Director, Paul Beamish

- Global Sales

- New Products

- Materials & Sustainability Update

- Service Update

- Marketing Update

- Q&A Session

- Closing

Official Welcome from our Managing Director, Paul Beamish

Paul opened both meetings, with the official welcome. The second quarter of 2021 has again, proved to be extremely lucrative. Where certain businesses have faltered under Covid, Ravenwood remains unaffected and is thriving. Sales are growing at a healthy and steady rate across all regions. And subsequently, sales across all of our associated technologies and labelling products, also continue to build.

Paul Beamish said: “Ravenwood has proven it’s resilience in a time of great uncertainty, whilst we have witnessed major disruption within many industry sectors.

He continued: “I would like to extend thanks to our amazing network of machinery distributors and printers, and of course, our staff at Ravenwood, who have remained dedicated and driven throughout the last year.”

Global Sales

Our Commercial Director, Dave Gooding, provided an update on sales across all machinery. As highlighted in our March meeting, sales in 2020 were our best year to date. This pattern of growth has continued into 2021, as we now approach the half way mark. Sales continue to grow with new machine builds taking us through until the end of September. Most notably for our Nobac 5000 range across the UK, Europe and Asia Pacific. And orders for our VXR range of machinery (label verification and pack inspection systems), are also increasing with many new installs scheduled to date. ‘Preloved’ Nobac 500 sales have also enjoyed a marked growth, as we continue to undertake multiple rebuilds. And last but certainly not least, we can also report that our Com500 coaters are selling extremely well with orders for coater upgrades.

New Products

James Read, our Ravenwood Product Manager, provided an update on the Nobac Stacker. The Stacker has been developed further and now has the functionality for adding variable data by way of integrating a Viper Inkjet printer. This data can include best before dates, product weight, cost and marketing mechanics. The Stacker is a great ‘entry level’ linerless label cutting and stacking machine. Perfect for smaller businesses with short print runs, for applying low volume linerless labels.

Dave then provided a brief update on the continued success of the Fruit Lid. The Fruit Lid is our latest label innovation, applied by the Nobac 5000L linerless applicator. The Fruit Lid was first trialled by Iceland Foods in October 2020 for its range of Conference Pears. The frozen food giant has set out to remove all plastic from its own label range in their ‘Plastic Free by 2023’ pledge. In a bid to assist Iceland in meeting this target, the retailer opted for a Fruit Lid and cardboard tray packaging concept. The lid and tray are produced from food grade cardboard and feature adhesive that is suitable for direct contact with food. The fruit lid and tray combined, offers a 100% reduction in plastic and is totally recyclable.

In less than a year, this packaging concept is now proving extremely popular and subsequently is now being trialled by many other food brands, in order to meet increasing demand. Retailers are coming under increasing pressure to move away from single use plastic which undoubtedly aids in the benefits of reducing Co2 emissions. The pack is now being supplied into many T1 and T2 retailers. It has also been adapted further, and is now suited to tomatoes, apples, pears, kiwis, plums and avocados.

Materials & Sustainability Update

Our materials specialist, Jez took over and updated us with the latest developments in linerless materials. Most notably, linerless films, food grade, water resistant and recycled stock. Ravenwood has also now developed two adhesives for direct contact with food. The adhesive features to our Fruit Lid. Jez then went on to discuss the latest in silicones and coatings and from there, the ‘Circle of Linerless’.

Ravenwood offers the complete linerless solution. We refer to this as the ‘Circle of Linerless’. A tried and tested formula that undoubtedly assists for the benefits of reducing Co2 emissions. The process guarantees for consistent and sustainable linerless labels across the globe.

- Approved suppliers for substrates, adhesives and silicone

- Joined up approach for the printing, coating, label application and end of line quality control with the VXR system

- Approved network of machinery distributors and printers

Jez then stated some interesting facts:

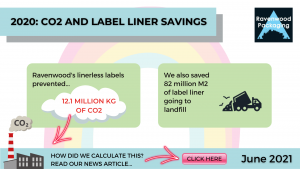

- In 2020, Ravenwood’s linerless labels prevented 12.1 million KG of Co2

- In the same year, Ravenwood prevented 82 million m2 of label liner going to landfill

- 90% of the Nobac 5000 machine weight is produced in the UK

- All parts are machined on site at our factory in Norwich or sourced within a 4 mile radius

How did we calculate this? Read our news article on how we saved 12.1 million KG of Co2

As you can see, in the food labelling industry, linerless massively contributes to the benefits of reducing Co2 emissions.

Jez then moved on to explaining our Preloved programme. The program focusses on refurbishments and rebuilds of all Ravenwood machinery out in the field. Where possible, Ravenwood reuses and recycles metal work, fixings, bearings and electrical motors.

And in closing his update, Jez then highlighted a new carbon offsetting initiative that Ravenwood is looking to partake in. The UK will bring all greenhouse gas emissions to net zero by 2050. Further updates on this will follow at our September quarterly meeting.

Service Update

The Service Update then followed for both the APAC and ROW regions.

Our UK Service Manager Rob, introduced our engineers and the areas that they are responsible for, across the globe. Rob also discussed the escalation process in terms of making contact. Our engineers provide full training and technical support as well as PDI for full print trials, and trays with products.

Sam Aloschi, our APAC Managing Director, introduced T3 Engineering for the support, service and training in the Asia Pacific region. Sam explained the protocols and guidelines for our network to follow.

Marketing Update

The final topic on the Agenda, was Marketing, presented by Natalie Bell, our Marketing Manager. Natalie discussed effective channels for file sharing, ahead of the new distributor and printer website build. Natalie also outlined practical initiatives for search engine optimisation (SEO) for improved search rankings on Google. Natalie concluded with events and news.

Q&A Session

A Q&A session then got underway with questions submitted by our distributors and printers, covering some interesting topics.

One particular question we would like to share was submitted by an anonymous customer, questioning a claim that they had ‘heard through the grapevine’.

Question: “One of your competitors claim that it takes 5 hours to change linerless label reels and trays in between products on a Ravenwood machine? Is this statement true?

Ravenwood’s Response: “No, this could not be further from the truth. It takes just 30 seconds to change the reel and 60 seconds to change the pack format.” This statement was then proved by way of playing the two videos below.

Ravenwood will hold its next quarterly online meeting in September. For further information, contact Natalie Bell, +44(0)1284 749144.