Denhay Farms has automated its packaging operations by integrating Ravenwood’s linerless technology for its bacon sleeves. The new linerless sleeves resemble traditional hand-applied sleeves but come supplied on a roll. The move has resulted in a significant reduction in labour and a boost in production line efficiency.

The award-winning bacon producer has successfully installed two state-of-the-art Ravenwood Nobac 5000 linerless applicators. The company has also partnered with UK-based linerless printer, ProPrint Group, to produce the new linerless sleeves.

“We’re absolutely thrilled with how seamlessly the linerless applicators and our new linerless sleeves have integrated into our production process. The machines have transformed our labelling operations, making it faster and more efficient, while the sleeves provide a premium, high-quality solution that perfectly complements Denhay’s brand,” said Jim Loescher, MD of Denhay Farms.

The switch to linerless comes as part of Denhay’s efforts to reduce manpower on the packaging line, improve staff welfare and add value by smarter spending. The transition from labour-intensive hand sleeving to fully automated labelling has been implemented across all Denhay’s own-label sliced bacon including the Spoilt Pig brand, and wholesale catering packs.

Denhay’s investment in two Ravenwood Nobac 5000 linerless applicators has fully optimised their production lines. These flexible applicators can sleeve a variety of fixed-weight pack formats and tray sizes, linking seamlessly to weigh scales for variable weight packs as well as check weighing. However, Denhay does not connect the Nobacs to scales in this application. The transition to linerless has not only improved packaging efficiency but also reduced storage and shipping space due to the compact nature of linerless reels compared to traditional manual sleeves.

Prior to linerless, employees spent long hours performing repetitive manual sleeving tasks. With the switch to linerless, staff now have more time to focus on other areas of production, leading to improved operations and a significant boost in morale.

“The wellbeing of our staff is at the heart of our operations. This transition has been a true ‘win-win’ – not only have we enhanced our labelling processes, but our team is also much happier with the new system. We’re so impressed with the results that we plan to expand the use of linerless technology across other products in our bacon range,” said Jim Loescher.

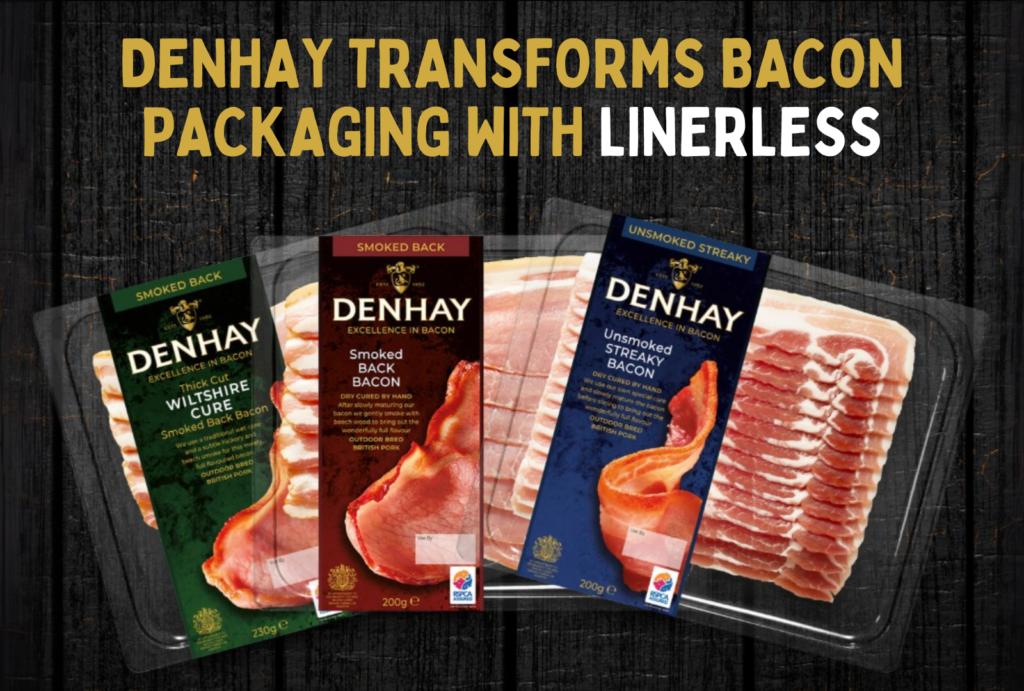

Throughout the transition, Denhay sought to retain the premium look and feel of their original cardboard sleeves. Ravenwood’s linerless sleeves, supplied on a roll and cut to size by the applicator, are designed to meet these aesthetic standards. These pressure-sensitive board reels are available in slideable or non-slideable versions, offering a high-quality, seamless finish. With no backing paper, linerless offers an eco-friendly and sustainable solution.

During initial trials, Denhay raised concerns over the visible white lines in the plate repeat pattern on the linerless sleeve. To resolve this, ProPrint introduced an innovative solution by filling the join with the same Pantone colour as the sleeve border during the artwork stage, referred to as an ‘infill’. This solution, which has since become a standard offering by ProPrint Group, ensures the sleeves maintain a flawless, premium appearance at no additional cost to the customer.

Founded in 1952, Denhay Farms has been producing award-winning bacon for almost 30 years. Their products are available through Tier 1 and Tier 2 retailers, as well as online platforms like Ocado and Amazon Fresh.

For further information, please contact Ravenwood’s marketing team at +44 (0)1284 749144.