Coding Equipment

Thermal Transfer Overprinting is the established technology of choice for a wide range of coding applications.

Compared to traditional contact coders such as hot-stamp or roller coders, thermal transfer overprinting offers

superior print quality and lower costs.

From label overprinting, to high speed digital coding on vertical bagging machines with flexible packaging, the Zodiac thermal transfer printer range is able to deliver fast print speeds, minimising downtime and ensuring the lowest possible cost of ownership.

Zodiac Eagle

The ICE Zodiac Eagle is the first airless 107mm TTO, eliminating the need for expensive compressed air and avoiding conventional air and energy settings that operators might over-adjust.

- Airless, all electronic printhead design with Intelligent MotionTM

- Modular design for OEM flexibility

- Industry-leading simple cassette with 1,200m ribbon capacity

- Top throughput up to 500 packs per minute

- Easy usability with CLARiTYTM interface to ensure the right code on the right product.

Zodiac Falcon

The ICE Zodiac Falcon is a 53mm TTO, which features built-in iAssureTM print-checking technology. The coder also eliminates the need for expensive compressed air, removing conventional air and energy settings that operators might over-adjust.

- iAssureTM – integrated print-checking technology

identifies code legibility issues - Airless, all electronic printhead design with Intelligent MotionTM

- Modular design for OEM flexibility

- Industry-leading simple cassette with 1,200m ribbon capacity

- Top throughput up to 250 packs per minute

- Easy usability with CLARiTYTM interface to ensure the right code on the right product

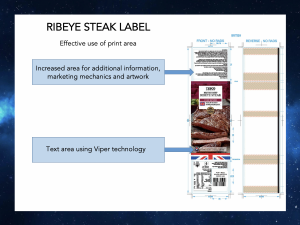

Viper Plus

The Viper Plus is a class leading thermal inkjet coder combining high performance and speed with extreme reliability, accuracy and no maintenance requirements. Suitable for printing on a range of porous and non-porous packaging materials for both primary and secondary applications, the Viper Plus uses HP®’s thermal inkjet (TIJ) technology.

- Retrofittable to our Nobac 5000 range and all Nobac 500s in the field.

- Ability to print ‘best before’ dates, product weight, cost and marketing mechanics.

- Speeds up to 150ppm are achievable.

- Printing can be applied to edge of trays and all linerless labels.

- Very economical to run as the Viper uses standard ink cartridges instead of ribbon, so avoiding downtime and cost for ribbon breaks.

- Printing strips of 25mm is easily achieved due to double stacked cartridges.

- Increased label print area due to Viper units being smaller with the ability to be moved to any position of the label.

- Fast, consistent, trouble free printing with excellent code clarity

- Printhead configuration for up to four printheads with print heights from 12.7mm to 50.8mm at print speeds up to 75 metres per minute

- Print up to four lines of 600dpi resolution vertical and horizontal text, bar codes, 2D data matrix codes and logos

- Maintenance free printer with no replacement parts other than the inkjet cartridge – just replace the ink when required and go

- Clean, mess free and easy to change HP® ink cartridges

- Selectable ink type setting ensures that the right ink is being used*

- Auto cartridge recognition*

- Ink level tracking that moves with the ink cartridge*

Visit the ICE website for further information.